Safety, Environment

& Health Management

Hanwha Energy Ensures Safe

And

Healthy Workplaces For All.

Hanwha Energy All Risk management system(HEARs)

Hanwha Energy All Risk Management system

Hanwha Energy has established its own Safety and Environmental Management System (HEARs) and

actively selects and implements key initiatives to create safe and healthy workplaces.

Striving for the

Achievement of

a Zero-Accident

Workplace

-

01

Expanding the Scope of Safety Management (Everyone on-site)

-

03

Company-Wide Expansion of Safety Management

-

02

Continuous Implementation of Safety Management & Operation of

the Safety Cycle -

04

Proactive Response to Government Safety Policies

Safety, Environment, and Health Policy

-

Hanwha

Hanwha Energy establishes and pursues Safety, Environment, and Health objectives to ensure that all employees understand the company’s core management values and prioritize safety and environmental protection across all operations.

-

Energy

As a leading company in the energy industry, we actively strive to reduce environmental pollutant emissions, comply with laws and agreements related to safety, environment, and health responsibilities, and faithfully implement internal management standards.

-

All

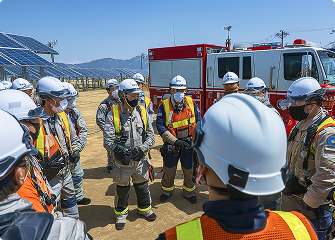

Hanwha Energy strives to cultivate a safety culture involving all employees and partner company personnel, ensuring safe work environments and promoting overall well-being to enhance the quality of life for everyone.

-

Risk Management

Hanwha Energy proactively prevents safety incidents by scientifically managing and mitigating potential hazards, while maintaining comprehensive preparedness for any emergencies.

-

System

Hanwha Energy actively engages in training to understand and uphold the importance of complying with the Safety, Environment, and Health system, and transparently communicates this policy to stakeholders to promote accountable SEH management.

Strict Adherence to Safety Rules and the Right to Halt Work

Hanwha Energy has established seven Absolute Safety Rules and enforces penalties for violations to eradicate safety incidents and ensure a zero-accident workplace. In addition, the company prioritizes employee safety by immediately halting work and implementing corrective measures whenever hazardous or risky conditions are identified.

Hanwha Energy Strictly Enforced Safety Rules

-

Prohibition of Work Without Safety Harness Secured

This rule applies to all movements, including climbing up and down, during work at heights. -

No Passage Under Suspended Loads

Includes Insufficient Control of Work Area Radius -

Prohibition of Work Without Power Disconnected

This rule applies to all work performed on equipment where power must be disconnected. -

No Entry into Confined Spaces Without Prior Oxygen and Gas Level Measurement

Includes Resumption of Work After Breaks -

Work Prohibited Without Assigned Fire Watch Personnel

Applies to Hot Work in CHS Areas and Within 11 Meters of Flammable Materials -

No Entry into Work Areas Without Wearing a Safety Helmet

Includes Improper Use of Safety Helmets (e.g., Unfastened Chin Straps) -

Working alone is strictly prohibited.

Applies to All Work Except Tasks Pre-Authorized for Solo Execution

Stop-Work Authority

-

I have the right to request that a supervisor or manager halt work whenever I identify a potential risk of accidents or injuries to myself or my colleagues.

-

Upon requesting a halt to work, I notify all surrounding personnel to ensure their awareness and safety.

-

I actively cooperate in identifying hazards and undertaking measures to eliminate risks related to a work stoppage.

-

I will not face any disadvantage for requesting a work stoppage.

All personnel have the right to exercise the authority to halt work.